1. Mould Technology

Project Management: The entire process of project management for mould business is implemented, with the participation of related departments involved but not limited to sales, engineering, and mould technique. The project management process focuses on delivery time, quality, and customer service as the core objectives.

flow chart

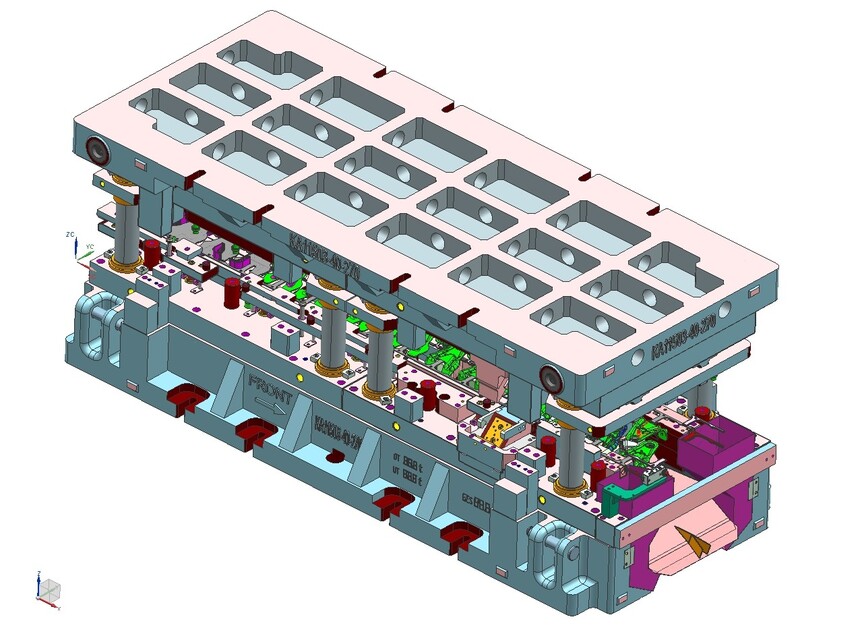

Mould Design: An experienced engineering team uses advanced software to analyze and optimize manufacturing processes, and provides customers with pre-design technical support (DFMER) to reduce mould modifications afterwards.

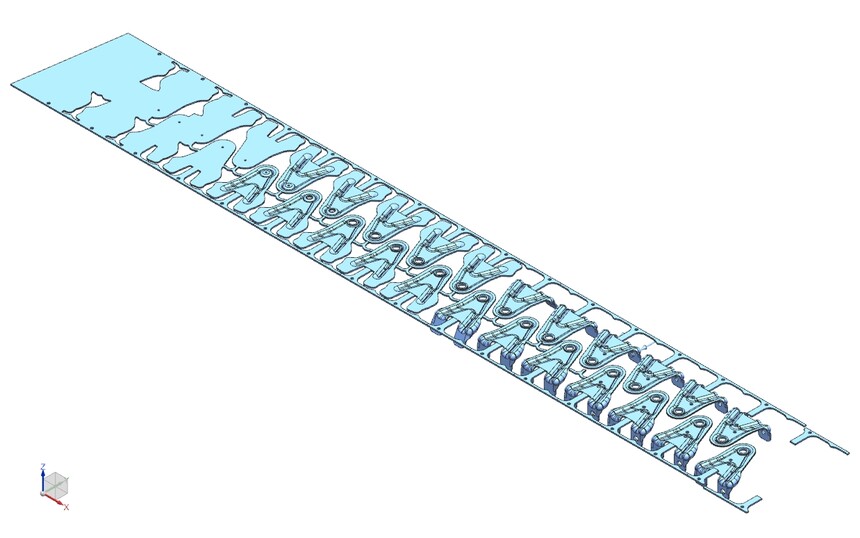

Design Course Mold Material belt

Mould manufacturing: multiple large-scale machining equipments, meeting the needs of various mould component processing; Professional personnel and precision inspection machine to assure 3D inspection of components and to ensure the accuracy.

Gantry CNC CNC machining center

Mould assembly and debugging: A debugging team with over 10-20 years of experience, specializing in effective solutions to mould debugging problems and reducing mould trial cycles

2. Stamping technology

Stamping processing: Professional stamping production, involving automotive components, electronic products, household appliances and metal parts in other fields.

For automotive sunroof components, Xinyongxu has over 15 years of production experience, excellent technology, and stable product quality.

Skylight 1 Skylight 2 Skylight 3

3. Welding technology

Production lines with welding robots from mainstream manufacturers: CO2 welding, laser welding, argon arc welding, servo resistance welding

Professional welding technology, automated welding equipment, and experienced welding personnel

MAG welding Laser welding Servo resistance welding